PVA

PVA Introduction

Polyvinyl alcohol (PVA), a white/yellowish granule or powder, is a stable, non-toxic, and water-soluble polymer. PVA possesses good film-forming property, and the film formed from it has excellent adhesion, solvent-resistance, abrasion-resistance, high tensile strength, and great oxygen barrier property. Due to PVA possesses both hydrophilic and hydrophobic functional groups, it can act as surfactant, and can be used as a protective colloid in polymer emulsification and suspension polymerization.

PVA Application:

(1) Warp sizing agent: Protective coating for natural fiber and synthetic fiber.

(2) Textile/Fabric finishing chemicals: Textile finisging chemicals used in processing, giving textile more stiff, anti-wrinkle, anti-shrinking, or other specific properties.

(3) Screen printing: Temporary adhesive for screen printing machine.

(4) Paper industry: Paper adhesive, re-wetting adhesive, surface coating, pigment coating, and internal sizing.

(5) Plywood, woodworking industry: Modifier for thermosetting resins.

(6) PVAc, PVC, PS: Stabilizer for emulsion, protective colloids.

(7) Construction industry: Cement additives, and molding adhesives.

(8) Raw material for PVA sponge and grinding discs sanding paper

(9) Packaging material: PVA films.

(10) Printing industry: Screen printing photosensitive films (photographic plate photosensitive film), and zinc plate printing photosensitive films.

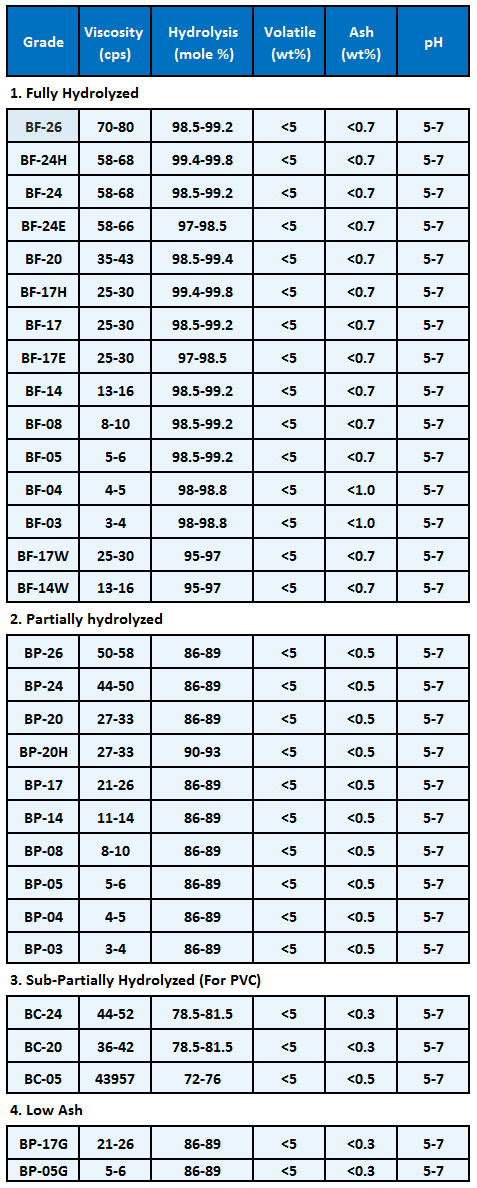

PVA Grades and Specifications

|

1.Standard Grades |

|

|

|

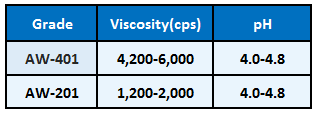

2.Tackified Grades |

|

|

|

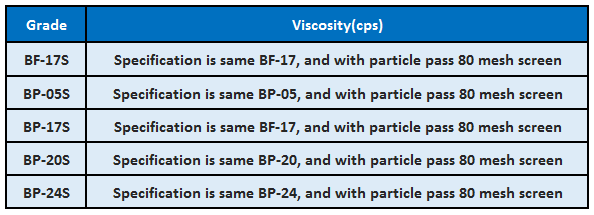

3.Fine Particle(5) Grades, S-grades |

|

|

|

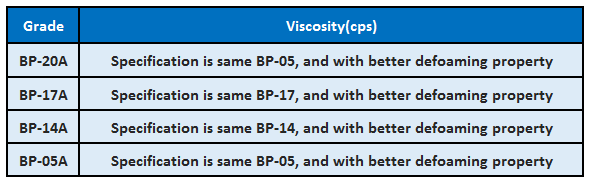

4.Low Foaming Grades |

|

|

Remark:

-

Viscosity of a 4 wt% standard grade PVA solution at 20°C which is determined by Brookfield Viscometer with UL adapter.

-

Calcuated as Na2O.

-

pH is determined by pH meter at 20°C.

-

Viscosity of a 10 wt% tackified grade PVA solution which is determined by Brookfield Viscometer at 25°C.

Particle size of standard grades is all passes through 10-mesh screen.

256 bit ssl encryption

256 bit ssl encryption